Sodium Silicate Precision Casting Stainless Steel Cast

Basic Info

Model No.: CF-069

Product Description

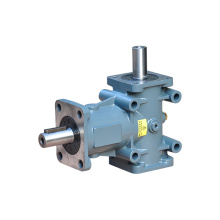

Model NO.: CF-069 Process: Investment Casting Application: Machinery Parts Surface Preparation: Sand Blast Machining Tolerance: +/-0.10mm Certification: SGS, CE, ISO 9001:2008 Material Type: Stainless Steel Surface Treatment: Blacking, Polishing, Anodize, Painting. Service: OEM Origine: Qingdao China Delivery Time: 30 Days After Receiving Payment Specification: ISO9001 SGS CE HS Code: 7307190000 Casting Method: Thermal Gravity Casting Molding Technics: Gravity Casting Material: Stainless Steel Surface Roughness: Ra6.3 Standard: ANSI Package: Pallet, Manmade Wooden Case or as Your Requirement Quality Control System: The Third Party Inspection, Self-Inspection. Production Ability: 150 Tons Per Month Supply Market: Global Machining: CNC Turning Milling Drilling Lathe Trademark: Chifine Origin: Jimo Qingdao City

Stainless Steel Cast Sodium Silicate Precision Casting

Product details:

1. Material: Iron, Stainless Steel, Carbon Steel, Bronze, Brass, Aluminum, aluminium alloys, copper alloys etc.

2. Weight range: 0.01 kg-200kg

3. Surface treatments: Shot blast, powder coating, mechanical polish, paint, plate etc.

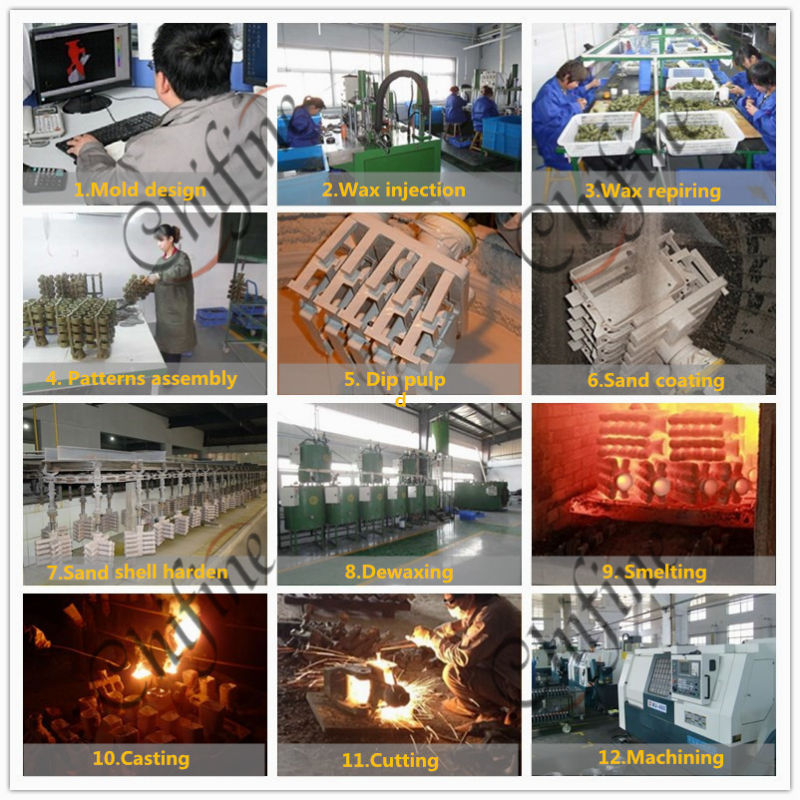

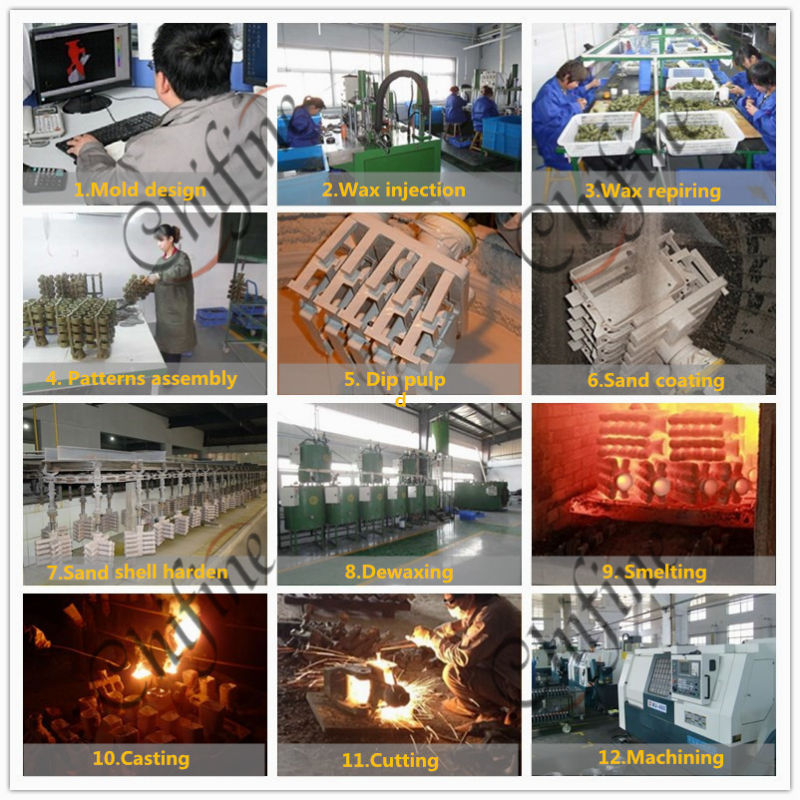

4. Tolerance: CT7-CT9

5. Application: Aerospace industries, power generation industries, complex shapes turbine blades, cooling systems, equiaxed blades, triggers, hammers, military, medical industries, commercial industries and automotive industries etc

6. Casting equipments: Intermediate frequency furnaces, high-frequency furnaces, Vacuum investment melting furnaces.

7. Refractory materialscasting: Silica, zircon, various aluminium silicates, alumina etc.

8. Binders: Ethyl silicate, silica sol, sodium silicate etc

9. Stainless steel lost wax investment casting

10.The Machining process:casting semifinished product- Hardening and tempering-Testing-Machining-Checking-Packing. Our advantage:

1).We are one of the leading exporters with a history of more than 20 years, enjoying an excellent reputation and keep a good relationship with many foreign companies, especially in Japan, Europe, America and Southeast Asia. 2).We have a lot of the high precise Machining equipment and high precision testing equipment, our manufactory also have a large number of the engineers. we can provide the best products and the best service for you. Our promise:

1).The delivery time and the package can be controled according to the customers' requirement completely.

2).we will produce the products seriously according to the drawings, and make sure all the products is suitable for the custoners. 3).We will communicate with the customers all the time about the products, we will send the pictures to the customers, so that they can know the Processing process

Quality Control:

We have a full set of quality control system to guarantee best product quality. Depending on the products, we can make different Item Testing Plan, Manufacturing procedure etc.

Raw material control

Chemistry spectrum analysis

Mechanical property

Metallographic analysis

Ultrasonic testing

Magnetic testing

Radiographic testing

Dimension inspection

Visual inspection

Penetrant testing

Leak testing

Hardness test

Micro-structure tester after heat treatment

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

Contact us if you need more details on Steel Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stainless Steel Casting、Precision Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Stainless Steel Cast Sodium Silicate Precision Casting

Product details:

1. Material: Iron, Stainless Steel, Carbon Steel, Bronze, Brass, Aluminum, aluminium alloys, copper alloys etc.

2. Weight range: 0.01 kg-200kg

3. Surface treatments: Shot blast, powder coating, mechanical polish, paint, plate etc.

4. Tolerance: CT7-CT9

5. Application: Aerospace industries, power generation industries, complex shapes turbine blades, cooling systems, equiaxed blades, triggers, hammers, military, medical industries, commercial industries and automotive industries etc

6. Casting equipments: Intermediate frequency furnaces, high-frequency furnaces, Vacuum investment melting furnaces.

7. Refractory materialscasting: Silica, zircon, various aluminium silicates, alumina etc.

8. Binders: Ethyl silicate, silica sol, sodium silicate etc

9. Stainless steel lost wax investment casting

10.The Machining process:casting semifinished product- Hardening and tempering-Testing-Machining-Checking-Packing. Our advantage:

1).We are one of the leading exporters with a history of more than 20 years, enjoying an excellent reputation and keep a good relationship with many foreign companies, especially in Japan, Europe, America and Southeast Asia. 2).We have a lot of the high precise Machining equipment and high precision testing equipment, our manufactory also have a large number of the engineers. we can provide the best products and the best service for you. Our promise:

1).The delivery time and the package can be controled according to the customers' requirement completely.

2).we will produce the products seriously according to the drawings, and make sure all the products is suitable for the custoners. 3).We will communicate with the customers all the time about the products, we will send the pictures to the customers, so that they can know the Processing process

Quality Control:

We have a full set of quality control system to guarantee best product quality. Depending on the products, we can make different Item Testing Plan, Manufacturing procedure etc.

Raw material control

Chemistry spectrum analysis

Mechanical property

Metallographic analysis

Ultrasonic testing

Magnetic testing

Radiographic testing

Dimension inspection

Visual inspection

Penetrant testing

Leak testing

Hardness test

Micro-structure tester after heat treatment

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

| Description | Lost wax casting |

| Technology | Silica sol binder |

| Lost wax | |

| Investment casting process | |

| Material | Stainless steel 301 |

| Standards | ASTM, JIS,AISI |

| BS, DIN, EN, ISO | |

| Advantages | Heat treatment to anneal, harden and temper metals |

| Non destructive testing:crack detection and x-ray | |

| Machining | |

| Surface finishing processes:including polishing, anodizing, painting, powder coating and plating. | |

| Capacities | 150tons per month |

| Applications | Marine hardware parts |

| Lock parts | |

| Auto parts | |

| Machinery parts | |

| Electric tools parts | |

| Stainless Steel Pipe & valve | |

| Hardware tools & other fields | |

| Weight range | 0.05KG~50KG |

| Service | OEM service are welcome |

Product Categories : Investment Casting > Others Investment Casting

Premium Related Products

Other Products

Hot Products

Enamel Range Cast Iron Grate for Gas Burner BracketSquare Ductile Cast Iron D400 Manhole Cover with FrameCNC Lathe Part Sewing Machine PartsScaffolding Ledger Head Part by Investment CastingASTM/DIN Stainless Steel Sand Casting ValveOEM Aluminum Alloy Gravity Casting ShellPrecision Metal Stamping Bracket with SteelTransmission Shaft Casting Yoke of AutoChina Top Ten Selling Products Slewing BearingHeavy Cylinder Forging3.6MW generator shaftLarge Module gearsSprocket GearForged Gear WheelFree Hot ForgingWear Resistant Steel Casting Parts