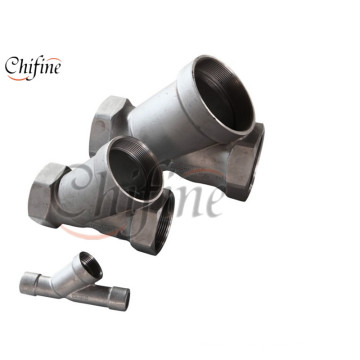

OEM Silica Sol Cast Products for Pipe Fitting Part

Basic Info

Model No.: CF-07

Product Description

Model NO.: CF-07 Process: Lost Wax Casting Application: Machinery Parts Surface Preparation: Sand Blast Machining Tolerance: +/-0.10mm Certification: ISO 9001:2008 Capacity: 150tons Per Month Packaging Detail: in Pallet or as Your Requirement Delivery Time: 30 Days After Receiving The Payment Technology: Lost Wax Casting+Machining Quality Control: Professional QC and Test Equipment Specification: ISO9001 SGS CE HS Code: 7307190000 Casting Method: Vacuum Aspirated Casting Molding Technics: Gravity Casting Material: Stainless Steel Surface Roughness: Ra6.3 Standard: ANSI Certificate: ISO9001 Service: OEM and ODM Machining: CNC Turning Milling Drilling Tolerance: CT7-CT9 Heat Treatment: Anealling Quenching Tempering Normalizing Trademark: Chifine Origin: Jimo Qingdao City Product Information

1. Material: Stainless Steel, Carbon Steel, Alloy Steel, like: SS304, SS316, 42CrMo4, 1Cr18Ni9Ti...

2. Process: Lost Wax Casting, Investment Casting by sodium silicate or silica sol and CNC machine...

3. Size: As per drawing or sample from 0.01 kg-500kgs unit weight.

4. Surface: Zinc-Plated, Hot Dip Galvanized, Polish, Painting, Lightly Oiled...

5. Non-Destructive Test: Ultronsic Test, Magnetic Particle Testing, X-Ray Testing...

6. Package: By plywood or wooden case, pallet...

Why you choose CHIFINE?

1. Excellent and professional service:

We have one high quality sales team including sale man and quality engineer and technics enginner.

2. Quality control:

The passing rate of finished product is no less than 99%. Every product need checking by many process.

3. Comprehensive service

Delivery within 30 days after receipt of down payment

Having be in this field for 20 years, covering ovearseas market of 30 different countries

Supply all the product with good quality and competitive price

4. Long term win-win cooperation

A reliable supplier and reputable supplier is the key to your business. CHIFINE must be the best choice for you!

FAQ

Q1: What is your MOQ?

A1: Our MOQ is 100 piece.

Q2: Do you offer free sample?

A2: We can provide you a sample but you need to pay for it and the freight, paypal and wester union is also accepted.

Q3: What is your payment term?

A3: 30% down payment after confirm the contract/PI, balance before shipment/copy of Bill of Lading

Q4: What is your lead time?

A4: 30 days after receipt the down payment usually. Urgent need please discuss with us to find a way out!

Q5: What technics would you have?

A5: We can do cast iron, cast steel, cast stainless steel, forged steel, die al casting and press steeel with CNC machining.

Q6: Are you manufacturer or trader?

A6: We are manufacturer owning a factory over 6000 sqm, workers over 200.

All the items mentioned in are made by ourself. But for ither items we do not have, we can look for you from other factories.

Q7: Can you make packing and logo as customer request?

A7: Yes we can, but you should pay for the extra cost caused.

Our Inspection Equipment:

Direct-reading spectrograph,metallographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.

Our Service:

1.Your inquiry related to our products or prices will be replied in 12 hours.

2.Individual formula according to customers' special drawing requests.

3.Manufacturer with large capacity,ensures the fast production cycle after

confirming the order.

4.Protection of sales area and private information for all of our customers.

Quality Control:

We have a full set of quality control system to guarantee best product quality. Depending on the products, we can make different Item Testing Plan, Manufacturing procedure etc.

Raw material control

Chemistry spectrum analysis

Mechanical property

Metallographic analysis

Ultrasonic testing

Magnetic testing

Radiographic testing

Dimension inspection

Visual inspection

Penetrant testing

Leak testing

Hardness test

Micro-structure tester after heat treatment

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

Contact us if you need more details on Water Glass Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stainless Steel Casting、Steel Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Material: Stainless Steel, Carbon Steel, Alloy Steel, like: SS304, SS316, 42CrMo4, 1Cr18Ni9Ti...

2. Process: Lost Wax Casting, Investment Casting by sodium silicate or silica sol and CNC machine...

3. Size: As per drawing or sample from 0.01 kg-500kgs unit weight.

4. Surface: Zinc-Plated, Hot Dip Galvanized, Polish, Painting, Lightly Oiled...

5. Non-Destructive Test: Ultronsic Test, Magnetic Particle Testing, X-Ray Testing...

6. Package: By plywood or wooden case, pallet...

Why you choose CHIFINE?

1. Excellent and professional service:

We have one high quality sales team including sale man and quality engineer and technics enginner.

2. Quality control:

The passing rate of finished product is no less than 99%. Every product need checking by many process.

3. Comprehensive service

Delivery within 30 days after receipt of down payment

Having be in this field for 20 years, covering ovearseas market of 30 different countries

Supply all the product with good quality and competitive price

4. Long term win-win cooperation

A reliable supplier and reputable supplier is the key to your business. CHIFINE must be the best choice for you!

FAQ

Q1: What is your MOQ?

A1: Our MOQ is 100 piece.

Q2: Do you offer free sample?

A2: We can provide you a sample but you need to pay for it and the freight, paypal and wester union is also accepted.

Q3: What is your payment term?

A3: 30% down payment after confirm the contract/PI, balance before shipment/copy of Bill of Lading

Q4: What is your lead time?

A4: 30 days after receipt the down payment usually. Urgent need please discuss with us to find a way out!

Q5: What technics would you have?

A5: We can do cast iron, cast steel, cast stainless steel, forged steel, die al casting and press steeel with CNC machining.

Q6: Are you manufacturer or trader?

A6: We are manufacturer owning a factory over 6000 sqm, workers over 200.

All the items mentioned in are made by ourself. But for ither items we do not have, we can look for you from other factories.

Q7: Can you make packing and logo as customer request?

A7: Yes we can, but you should pay for the extra cost caused.

Our Inspection Equipment:

Direct-reading spectrograph,metallographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.

Our Service:

1.Your inquiry related to our products or prices will be replied in 12 hours.

2.Individual formula according to customers' special drawing requests.

3.Manufacturer with large capacity,ensures the fast production cycle after

confirming the order.

4.Protection of sales area and private information for all of our customers.

Quality Control:

We have a full set of quality control system to guarantee best product quality. Depending on the products, we can make different Item Testing Plan, Manufacturing procedure etc.

Raw material control

Chemistry spectrum analysis

Mechanical property

Metallographic analysis

Ultrasonic testing

Magnetic testing

Radiographic testing

Dimension inspection

Visual inspection

Penetrant testing

Leak testing

Hardness test

Micro-structure tester after heat treatment

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

| Material Available | Stainless steel, Carbon steel, Alloy Steel, etc |

| Process | Investment/Lost wax casting(waterglass/sodium silicate proces) |

| Surface finish | Shot blasting, sand blasting, polishing, machining, acid-cleanup |

| Weight | About 0.01-60kg |

| Production facility | *Casting facility:Wax injector, electric furnace, heat treatment furnace, cutting head machine, shot-blasting machine, sand-blasting machine *Machining facility:CNC, NC lathe, ordinary machine tools, linear cutting machine, NC milling machine, polishing machine |

| Heat treatment | Normalizing/Quenching/ Tempering |

| Test facility | Spectrometer, Tensile test machine, Impact tester, Hardness test machine |

Contact us if you need more details on Water Glass Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stainless Steel Casting、Steel Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Investment Casting > Others Investment Casting

Premium Related Products

Other Products

Hot Products

Enamel Range Cast Iron Grate for Gas Burner BracketSquare Ductile Cast Iron D400 Manhole Cover with FrameCNC Lathe Part Sewing Machine PartsScaffolding Ledger Head Part by Investment CastingASTM/DIN Stainless Steel Sand Casting ValveOEM Aluminum Alloy Gravity Casting ShellPrecision Metal Stamping Bracket with SteelTransmission Shaft Casting Yoke of AutoChina Top Ten Selling Products Slewing BearingHeavy Cylinder Forging3.6MW generator shaftLarge Module gearsSprocket GearForged Gear WheelFree Hot ForgingWear Resistant Steel Casting Parts