Investment Stainless Steel Casting Ship/Boat/Marine Part

Basic Info

Model No.: CF-055

Product Description

Model NO.: CF-055 Process: Investment Casting Application: Machinery Parts Surface Preparation: Sand Blast Machining Tolerance: +/-0.10mm Certification: SGS, CE, ISO 9001:2008 Certificate: ISO9001 SGS Ce Brand: Chifine Service: OEM and ODM Heat Treatment: Normalizing ,Tempering ,Quenching,Anealling Quality Control: Professional QC and Test Equipment Transport Package: in Pallet or as Your Requirment Origin: Jimo City Qingdao Casting Method: Thermal Gravity Casting Molding Technics: Gravity Casting Material: Stainless Steel Surface Roughness: Ra6.3 Standard: ASTM Origine: Qingdao Supply Market: Global Machining: CNC Turning Milling Drilling Lathe Delivery Time: 30 Days After Receiving The Payment Supply Ability: 150tons Per Month Trademark: Chifine Specification: ISO9001 SGS CE HS Code: 7307190000 Product Information:

1.Material:Gray iron, ductile iron, malleable iron, Carbon Steel,Alloy steel, stainless steel, aluminum, bronze, brass,etc.2.Standard:JIS, DIN, ASTM, BS,GOST 3.Process:Sand Casting, Investment Casting,Precision Casting,Forging,Stamping,CNC Machining. 4.Surface Treatment:Electro Zinc Plating Hot deep zinc plating,Electrophoresis,Powder coating,Painting ,Shoot blasting etc. 5.Heat treatment:Induction furnace for raw material heating.Heat treatment of continuous quench+temper+carburization available. 6.Machining:CNC machining centers for further machining process.

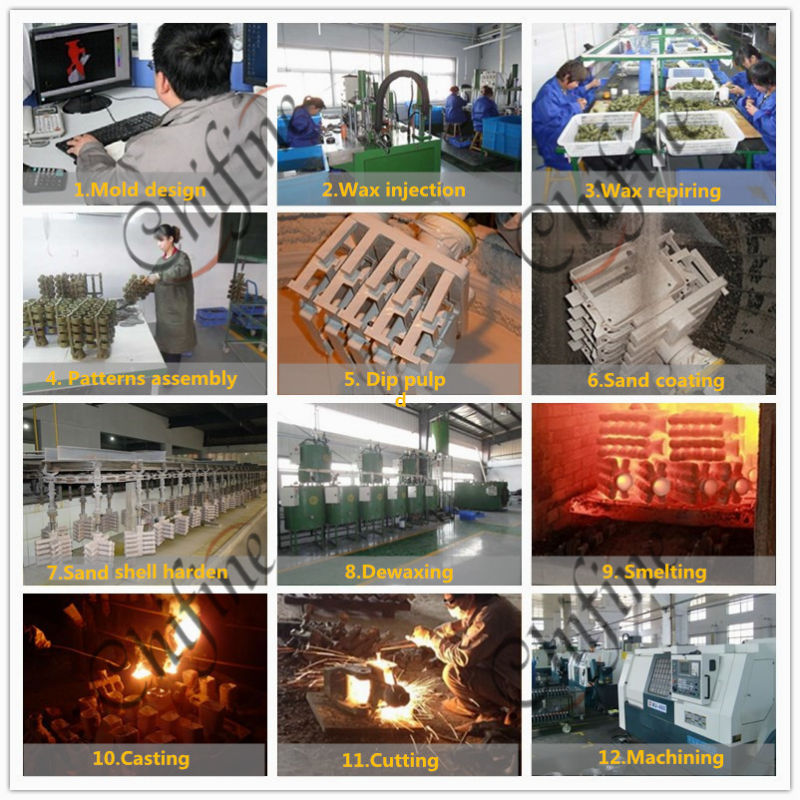

Process:

1. Drawing control

Confidentiality-Be confidential to the customers'drawings.

Check- Technician checks the drawings and confirms dimensions

Confirmation - Confirm the production process & inspection process according to the drawings

2. Mold making control

Inspect the dimensions and material according to drawing.

Send test reports and photos to customers.

3. Raw Casting control

Produce according to the production tracking form

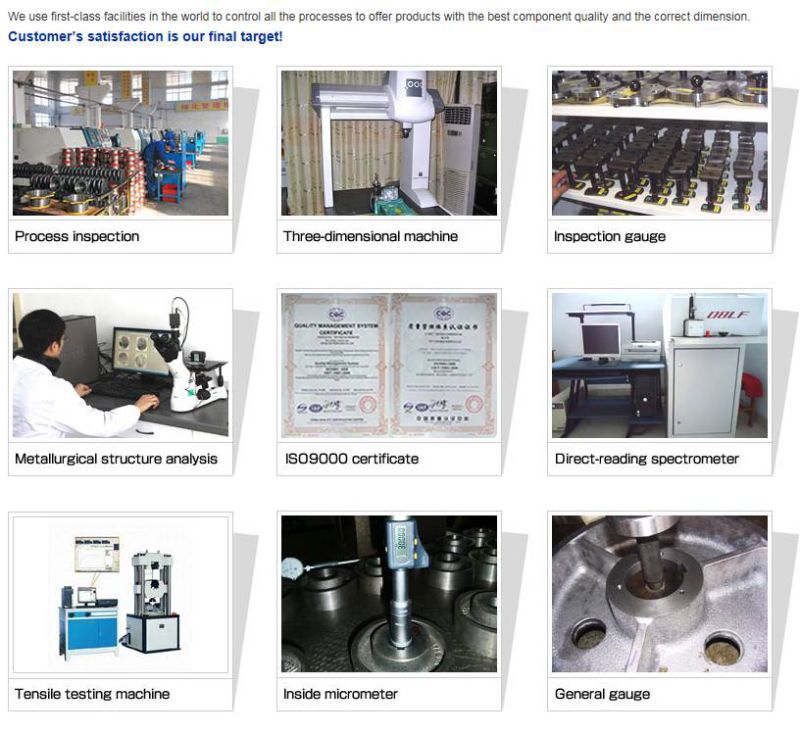

Use advanced inspection equipments to ensure internal quality of the product.

Check the test bar and record relevant information to each bulk.

Send the photos and test data of each step to customers.

4. Machining process control

Produce the samples according to the confirmed casting process.

Train the relevant staff before producing according to the machining and inspection process.

Our inspector will track the quality and time of the products during producing. Any problems on quality and process must be feedback to our customers.

Do the finial inspections to the products and send the relevant data and finished product photos to the customers.

5. Packing and Delivery control

Determine the size & material of the box according to the shape & number of products.

Taking different anti-rust protection to products according the delivery time

Put dimensional reports, chemical & mechanical documents, test bar and photos into the packing box

Send the photos of whole packing process to customers.

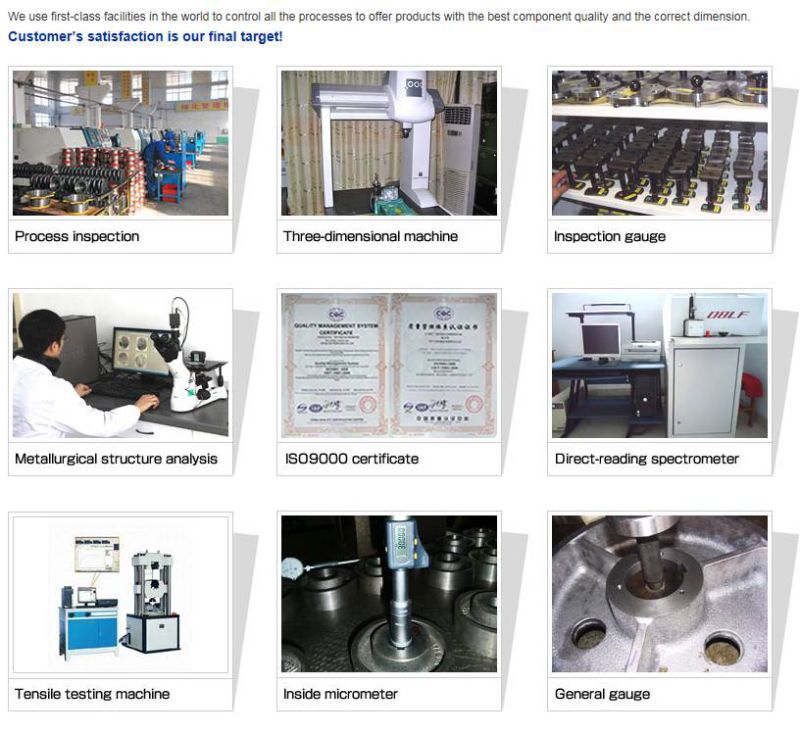

Qingdao Chifine Machinery Co.,Ltd is one famous company in China which specialized in various metal casting products with over 10 years experience located in Qingdao China.It covers a comprehensive range of forging, stamping, sand casting, investment casting, Die Casting and machining and was widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering

As a professional company, Chifine have four groups of experienced teams to be in charge of different work:

Project team-customer service

Engineering team-provide R&D and technical support

QC team-productive process control and incoming parts inspection

Our company advantages

1.Developing engineering and customed products as required.

2.Chifine own R&D center could make the clients' ideas to be actual products with support from related engineers from different fields.

3.Experienced technical and inspection team.

4.The whole production cycle is monitored by our Quality Management System

5.Very strict with quality control and delivery time.

6.Regular production report.

Contact us if you need more details on Boat Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ship Part、Casting Boat Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Boat Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ship Part、Casting Boat Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Material:Gray iron, ductile iron, malleable iron, Carbon Steel,Alloy steel, stainless steel, aluminum, bronze, brass,etc.2.Standard:JIS, DIN, ASTM, BS,GOST 3.Process:Sand Casting, Investment Casting,Precision Casting,Forging,Stamping,CNC Machining. 4.Surface Treatment:Electro Zinc Plating Hot deep zinc plating,Electrophoresis,Powder coating,Painting ,Shoot blasting etc. 5.Heat treatment:Induction furnace for raw material heating.Heat treatment of continuous quench+temper+carburization available. 6.Machining:CNC machining centers for further machining process.

Process:

1. Drawing control

Confidentiality-Be confidential to the customers'drawings.

Check- Technician checks the drawings and confirms dimensions

Confirmation - Confirm the production process & inspection process according to the drawings

2. Mold making control

Inspect the dimensions and material according to drawing.

Send test reports and photos to customers.

3. Raw Casting control

Produce according to the production tracking form

Use advanced inspection equipments to ensure internal quality of the product.

Check the test bar and record relevant information to each bulk.

Send the photos and test data of each step to customers.

4. Machining process control

Produce the samples according to the confirmed casting process.

Train the relevant staff before producing according to the machining and inspection process.

Our inspector will track the quality and time of the products during producing. Any problems on quality and process must be feedback to our customers.

Do the finial inspections to the products and send the relevant data and finished product photos to the customers.

5. Packing and Delivery control

Determine the size & material of the box according to the shape & number of products.

Taking different anti-rust protection to products according the delivery time

Put dimensional reports, chemical & mechanical documents, test bar and photos into the packing box

Send the photos of whole packing process to customers.

| PROCESS | MATERIAL | STANDARD | |

| SAND CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| INVESTMENT CASTING | Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| STAMPING MACHINING | STAMPING MACHINING | All metal material | |

Qingdao Chifine Machinery Co.,Ltd is one famous company in China which specialized in various metal casting products with over 10 years experience located in Qingdao China.It covers a comprehensive range of forging, stamping, sand casting, investment casting, Die Casting and machining and was widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering

As a professional company, Chifine have four groups of experienced teams to be in charge of different work:

Project team-customer service

Engineering team-provide R&D and technical support

QC team-productive process control and incoming parts inspection

Our company advantages

1.Developing engineering and customed products as required.

2.Chifine own R&D center could make the clients' ideas to be actual products with support from related engineers from different fields.

3.Experienced technical and inspection team.

4.The whole production cycle is monitored by our Quality Management System

5.Very strict with quality control and delivery time.

6.Regular production report.

Contact us if you need more details on Boat Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ship Part、Casting Boat Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Boat Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ship Part、Casting Boat Part. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Investment Casting > Stainless Steel

Premium Related Products

Other Products

Hot Products

Enamel Range Cast Iron Grate for Gas Burner BracketSquare Ductile Cast Iron D400 Manhole Cover with FrameCNC Lathe Part Sewing Machine PartsScaffolding Ledger Head Part by Investment CastingASTM/DIN Stainless Steel Sand Casting ValveOEM Aluminum Alloy Gravity Casting ShellPrecision Metal Stamping Bracket with SteelTransmission Shaft Casting Yoke of AutoChina Top Ten Selling Products Slewing BearingHeavy Cylinder Forging3.6MW generator shaftLarge Module gearsSprocket GearForged Gear WheelFree Hot ForgingWear Resistant Steel Casting Parts